On 21 and 22 April the

SPIRE consortium and the European Commission organised a workshop on the impact

of the SPIRE PPP and associated FP7 and Horizon 2020 projects. The workshop

took place at Committee of the Regions offices in Brussels. This event was billed

as the first in a series of annual impact workshops and saw some 40 process-related

projects represented: 12 from Horizon 2020 and 28 from FP7. SusChem News will be looking to follow up on some of these projects and investigate their outcomes and potential impact in more detail.

Chairing the opening session José Lorenzo Vallés from the European

Commission said that PPPs offer a framework to encourage projects to work

together and supports transfer of results to the market. But key issues remain:

What impact is actually achieved? How can impact be improved? And specifically

for SPIRE how is it adding value?

Søren

Bøwadt of the European Commission outlined the current status of SPIRE projects

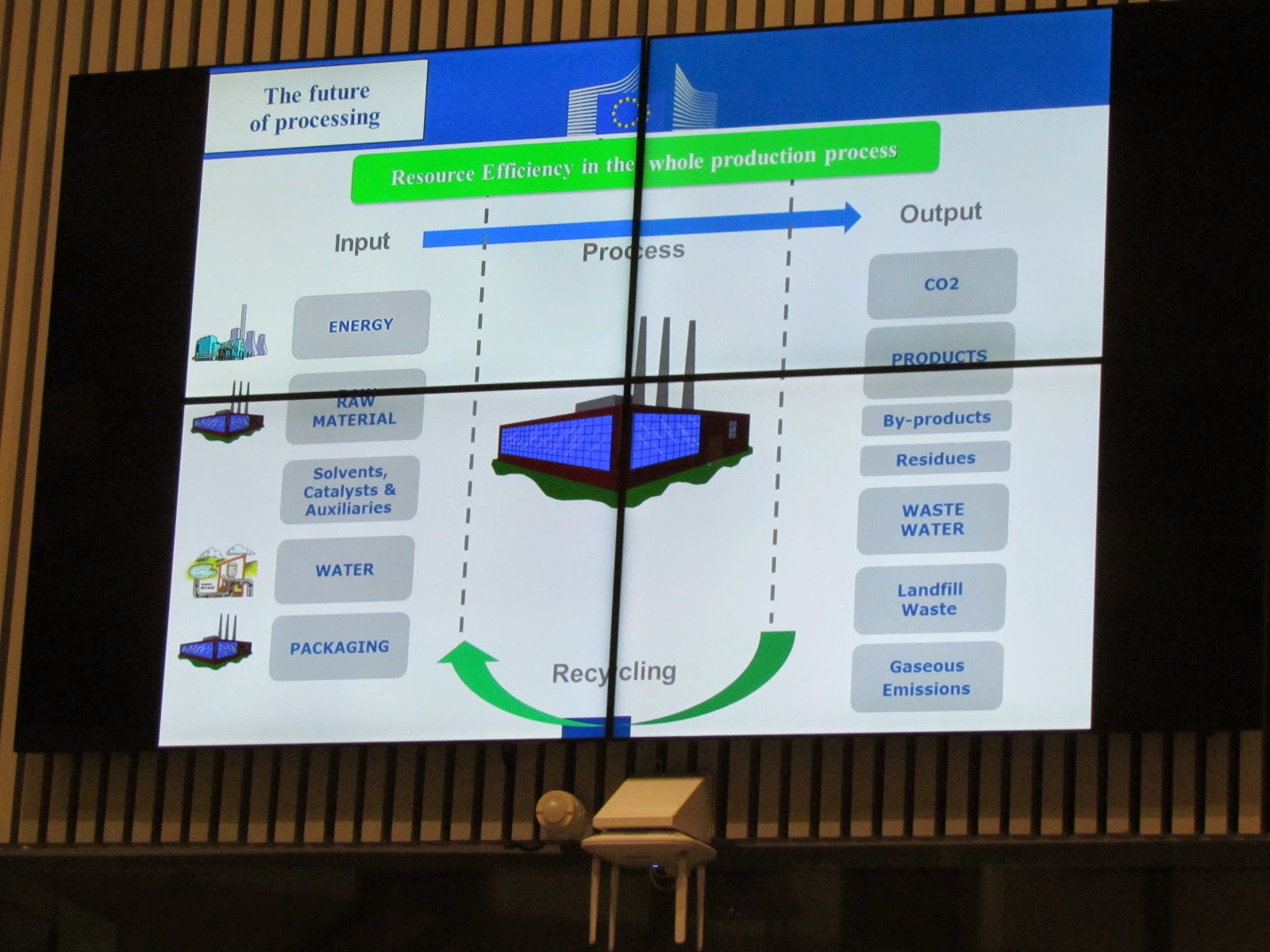

in Horizon 2020. “SPIRE is an integral part of the circular economy,” he

stated. “As development of the circular economy requires significant RTD and

Innovation investments.”

Project presentations

The first day of the workshop saw presentations on project clusters with the aim of assessing the impact achieved, the potential uptake and exploitation, the benefits of clustering and identifying good practise to maximise impact.

The first day of the workshop saw presentations on project clusters with the aim of assessing the impact achieved, the potential uptake and exploitation, the benefits of clustering and identifying good practise to maximise impact.

The first session covered efficient processes.

Prof Andrzej Gorak of TU Dortmund presented results from eight projects in the

domain of process optimisation: COPIRIDE, F3-Factory, INCAS, POLYCAT, SYNFLOW, MAPSYN, INNOREX, and ALTEREGO.

Prof Gorak highlighted a range of technical

impacts from the development of highly selective hydrogenation catalysts

through new synthesis methodologies, and novel modularised processes, process

intensification and advanced design of integrated technologies, to combined

reaction and separation processes. Cost reduction, better safety

characteristics and improved resource and energy efficiency were also targeted.

Adaptable

processes

Denilson da Silva Perez of Institut Technologique Foret Cellulose

Bois-construction Ameublement (FCBA) based in Bordeaux presented a

cluster of projects looking to enable the use of renewable resources, such as biomass

and residues from different EU regions, and increase the efficiency and

economic viability of the transport of pre-treated biomass from decentralised rural locations.

The projects were AFORE, EUROBIOREF, FASTCARD, BIOGO, CASCATBEL, STEAMBIO, MOBILE FLIP, and PRODIAS.

Five projects in the domain of modelling and

elements of process control were described by Sebastian Engell of TU Dortmund. All

were of high industrial relevance and covered process control and resource

efficiency monitoring. Projects COOPOL and OPTICO focus on control: OPTICO examining multi-scale,

multi-phase phenomena to enable new technology and processes with process

improvements of ~17%, while COOPOL worked on control and real-time optimisation

providing a framework for intensification of chemical processes within a

limited timeframe.

MORE looked at near real time

monitoring of resource efficiency indicators (REIs) producing novel analytics,

and a new process dashboard including visualisation of multi-dimensional REIs.

Similarly TOP-REF looked to develop

homogeneous audit and diagnosis tools based on thermo-economics techniques.

Finally REFFIBRE modelled the impact of innovations on the circular

economy for improved resource efficiency.

Integrated

process control

Peter Singstad of Norwegian company Cybernetica

AS described four SPIRE projects covering control, instrumentation and mathematical

modelling with potential to transfer technology and knowledge between sectors.

RECOBA covered real time sensing, advanced control

and optimisation of batch processes that could save energy and raw materials.

From an economic standpoint the project could lead to material savings of typically

to 1-5% and up to 25%. The DISIRE project also used

integrated process control based on distributed in-situ sensors to optimise belt

conveyor transportation schemes used in minerals, mining and industrial

combustion processes. Similarly CONSENS (website under

construction) used integrated control and sensing for sustainable operation of

flexible intensified processes. The ProPAT project was also developing

an integrated process control platform able to utilise individual sensors and

methods for multi-sensory inputs leading to more efficient control of

processes.

Sebastian Engell noted that for control

solutions there was a huge gap between proven technology and what is actually applied

broadly in industry. Technical innovation was slow to permeate through to the

factory floor despite the relatively low investment required and low risk. This

needed to be improved to maximise impact.

Sustainability

and Circular Economy

The first domain discussed in the field of

sustainability and the circular economy was integrated management of resources.

Anna Sagar of SP Technical Research in Sweden described four projects E4WATER (developing and

implementing more efficient and sustainable water management in the chemical

industry), R4R (improving research

and cooperation between chemical regions in Europe), MefO2 (using waste CO2 to make methanol) and TASIO (demonstrating a modular approach to waste heat recovery

in the cement industry).

Jan Meneve of VITO then described projects

involved in waste recovery. He defined three waves of waste management: first remediation

driven by health and safety concepts; then commodity recycling driven by volume

issues; and now specifity recycling driven by value considerations. This last

wave was the focus of nine projects: RECLAIM, REMANENCE, HydroWEEE, RECYVAL-NANO, REEcover, RecycAl, ReFraSort, C2CA, and BIOMETALdemo. Jan stated that recycling by definition

represented the use of smart green technologies that reduced waste generation

while improving resource efficiency.

Life

cycle Management

The final set of three projects on day one were

presented by Amy Peace of BRITEST Limited and concerned lifecycle management. All

focused on developing recommendations on the current use of sustainability

indicators, tools and methodologies. There was close cooperation between the

three projects: SAMT was gathering

industrial best practise; STYLE was a pragmatic project

looking to see what can be achieved on a day-to-day basis; and MEASURE had the most academic focus to develop an

in-depth cross-sectorial Lifecycle Analysis (LCA) methodology. The joint aim is

to ensure that the sustainability impact of new SPIRE technologies can be

evaluated on a consistent basis.

Plenary

and panel discussion

The second day of the workshop was opened by Clara

de la Torre, Director ‘Key Enabling Technologies’ (KETs) at DG Research and

Innovation (below, right). She noted that SPIRE was now the second largest PPP in Horizon 2020

after the Factories of the Future initiative and she

stressed the importance of financial leverage in PPPs. “PPPs follow the same

processes as the normal Horizon 2020 programme, but represent a long-term commitment

by the Commission to support, and by industry to invest,” said Ms de la Torre.

But she emphasised that “Impact is the name of the game!”

This theme was taken up by Dr Klaus Sommer, Chairman

of A. SPIRE (above, left). “[SPIRE] must focus on the ‘wow’ factor,” he said. “Finding good

stories to promote in terms of impact and outcomes.” The integrated character

of SPIRE allowed for a systematic approach to impact from raw materials to end

user industries and R&D to the market.

He summarised the expected impacts of SPIRE: to

integrate and demonstrate at least 40 innovative systems and technologies. This

meant every SPIRE member needed to contribute. He also emphasised the need to

make it easier for SMEs to get involved. “The advantage of being in SPIRE is

that you can contribute to shaping the future,” concluded Dr Sommer. “Rather

than just experience it.”

The instruments available from the European

Investment Bank (EIB) for financing investments in KETs were outlined by Piermario

Di Pietro with a specific focus on the InnovFin scheme. He also sought

views on access-to-finance experiences, current or past, from established larger

SMEs or small mid-caps firms (minimum € 5 million annual turnover).

The next session highlighted four projects that

have made high impact: SYNFLOW (looking at innovative

synthesis in continuous flow operations in particular to reduce waste in the

production of pharmaceuticals and other fine chemicals); COOPOL (looking at control of

emulsion polymerisation; specifically intensifying this 100 year-old process); E4Water (looking at increasing

eco-efficiency in industrial water management); and R4R, (involving analysis of innovation systems and

research agendas in six regional clusters).

The workshop’s formal sessions concluded with a

wide ranging panel discussion on maximising impact and successful innovation strategy.

Concluding

remarks

The meeting rapporteur, Keith Simons (below), remarked

that the FP7 projects presented had clearly developed new technology and

methodologies. But he also noted that there was a need to communicate success

in terms of hard economic figures. He knew that some excellent process

technology success stories were out there that could be used to promote SPIRE. He

thought that SPIRE as a concept had been a political masterstroke and that European

process community has taken up the challenge. He believed that SPIRE had

already had an impact, but needed to better recognise and exploit success.

Loredana Ghinea, chief executive of the A.SPIRE

consortium, outlined the objectives for SPIRE in the coming 12 months. These

included preparing for the Horizon 2020 work programmes in 2016-17. There will be

a SPIRE brokerage event on 29-30 June and a SPIRE knowledge and dissemination

platform was planned to be available by January 2016. This would help to forge connections

between businesses and connect the work programmes with actual projects to

enable a continuing discussion on future programme development.

A thematic workshop will be held later in 2015 bringing

together the different SPIRE sectors to identify and tackle common challenges.

The PPP also aims to follow up with all SPIRE projects and provide support for communication

and dissemination activities.

No comments:

Post a Comment

Please post your comment here. Please note that this newsblog is not moderated.

Note: only a member of this blog may post a comment.